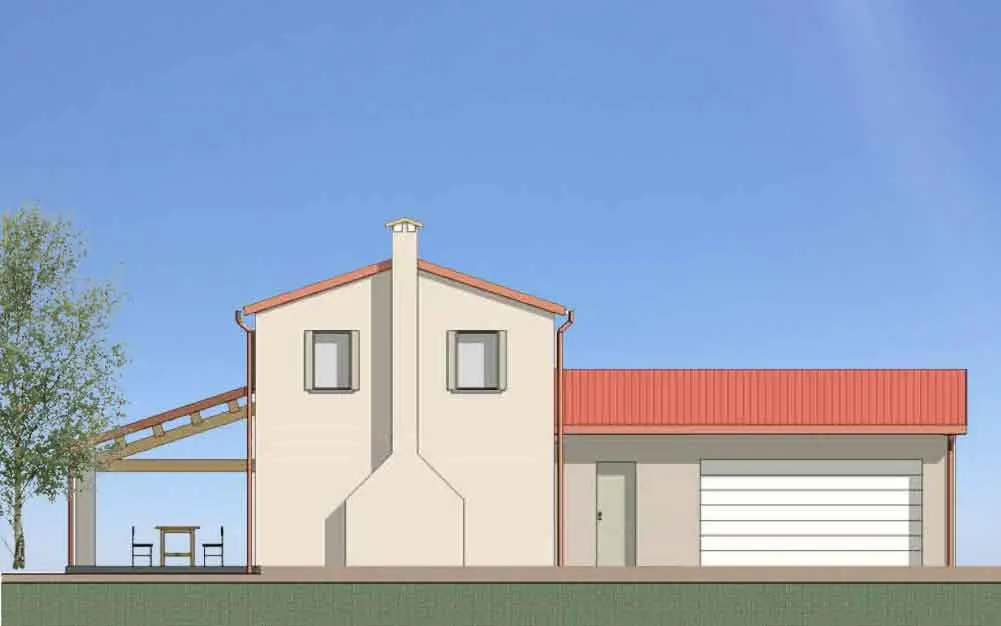

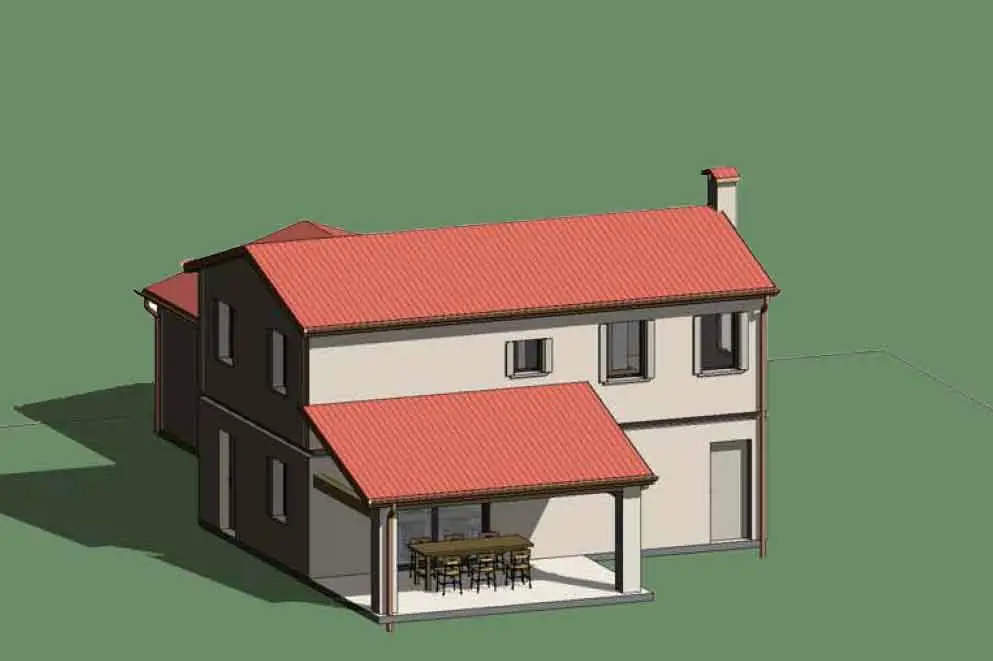

This three-room wooden house design fits perfectly into the environment of the Veneto countryside.

Attunement with the surrounding environment

This is a project designed specifically for a construction practice of demolition and reconstruction in an agricultural environment.

Thanks to the regulations employed, the project provided tax relief for the developer and an increase in the pre-existing volume.

When the land is located in an agricultural zone, the type of intervention must be subject to the standards contemplated by local urban intervention plans. Generally, these projects require construction that respects the type of traditional buildings found in agricultural land.

In our wooden houses we can include traditional eaves and traditional windows with typical Paduan, Venetian or Vicenza-style shutters and equip the exterior facades with the typical traditional plaster finish.

The windows and doors we use are also made of wood, and this guarantees the validity of the product.

Our wooden houses are developed with the most advanced technology available on the construction market today, yet they can blend seamlessly into the surrounding agricultural environment.

The building envelope

The thickness of our walls is about 40 cm; this is quite similar to the thickness found in brick or stone masonry. The difference is that the thickness of our masonry is mainly made up of highly insulating material.

This externally is not noticeable as the wall can be finished in traditional plaster based on classic colors.

Facade windows may or may not be framed, this depends on the taste of our clients both solutions are within the local tradition.

Plants

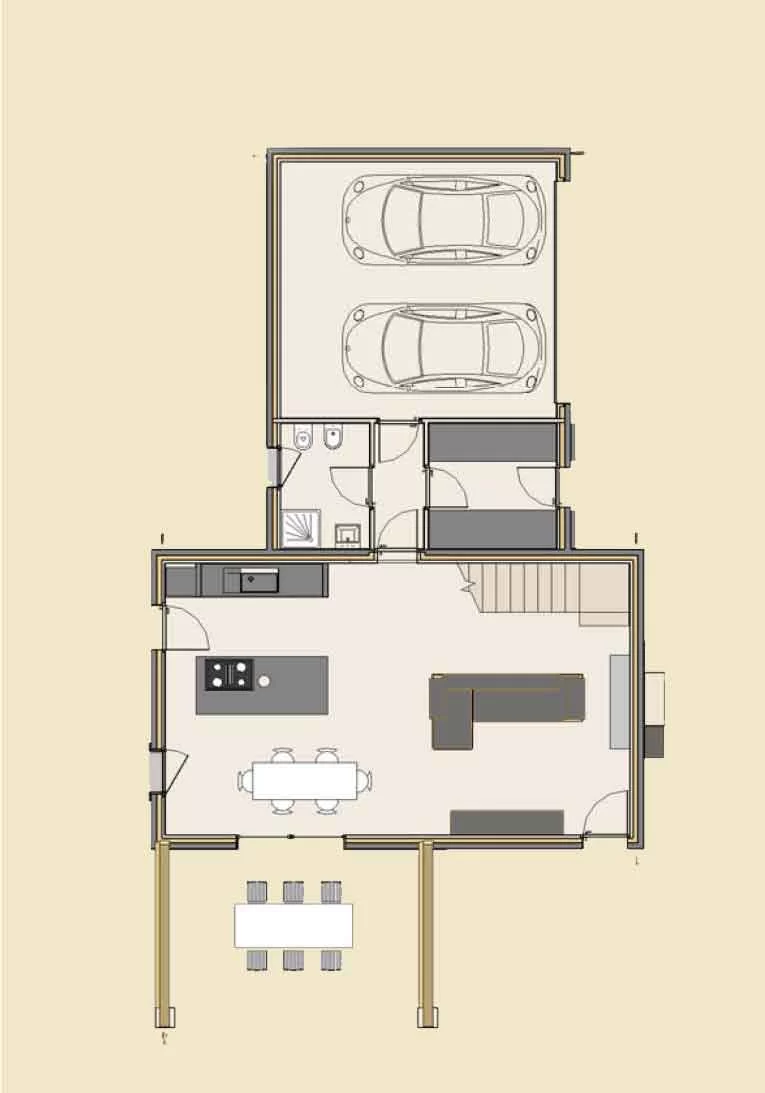

The floor plan of the property includes on the ground floor:

- living room/open-plan kitchen of 51 sqm;

- WC of 4.6 sq. m;

- technical room / laundry room of 6.8 sq m;

- garage of 30 sq m;

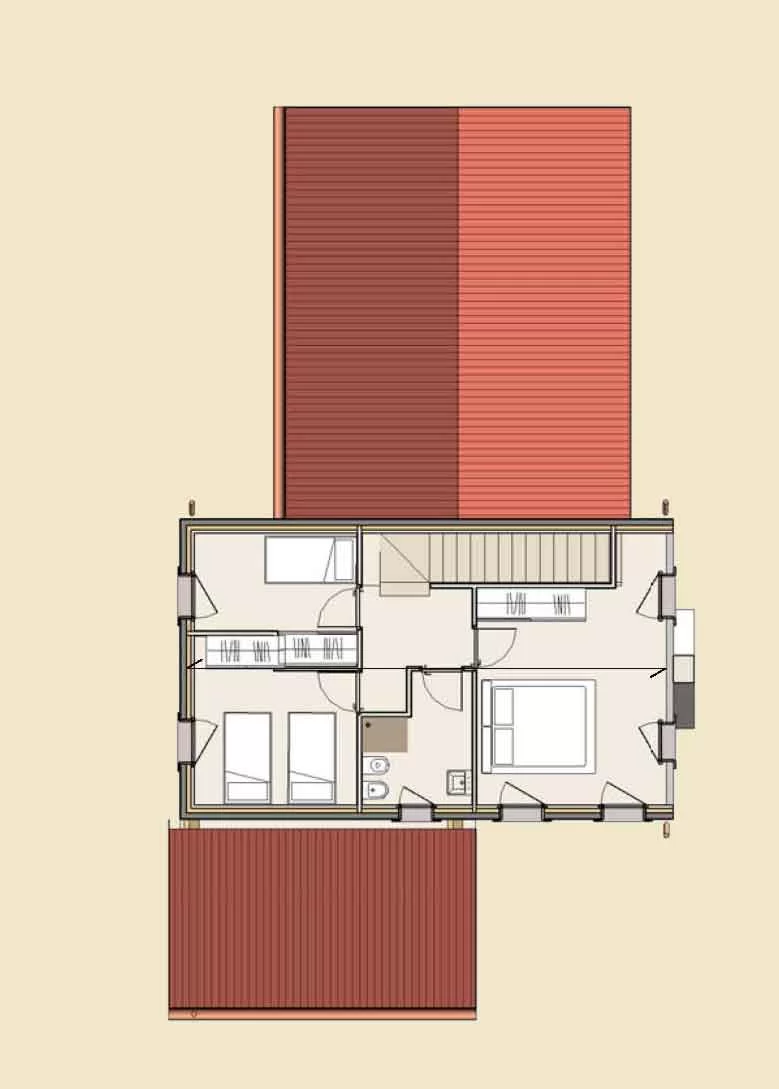

On the first floor we find:

- Two single rooms of 10 sq m;

- a double bedroom of 16 sq. m;

- a 5.5-square-meter bathroom.

In total, the building is 180 square meters.

Masonry

Bearing perimeter walls made of X Lam of certified production by Artuso Legnami company http://www.artusolegnami.it/ Supply and installation of prefabricated wall of the standard type 100 mm complete with Rothoblaas fasteners

http://www.rothoblaas.com/it/it/home.html or Borga Italia.

Load-bearing wall in X Lam, composed, in sequence from inside to outside by :

- double sheet of 12.5 mm plasterboard; in the case of facing the bathroom, water-repellent plasterboard will be used;

- 50 mm cavity for plant passage with 5×4 cm fir laths insulated with 50 mm rock wool (or thicker for any larger diameter pipes);

- 100 mm X Lam 3-layer load-bearing wall (depending on structural calculations);

- 200 mm rock wool coat density >135 kg/m3, l = 0.037 W/mK;

- 5mm mineral plaster with plaster carrier mesh and siloxane finish.

Facilities

Thermal power plant

The main generator will be an air-to-water heat pump to create hot water for heating and Domestic Hot Water production and cool water for air conditioning and dehumidification in the summer phase.

A 300-liter boiler is provided for the production and storage of Domestic Hot Water for sanitary uses.

Heating/cooling system

Heating/cooling will be done in radiant wall mode. Plasterboard panels will be built into the wall with pipes embedded inside where hot water created by the heat pump will flow and give the room the energy needed to heat. In the same panels will flow cool water in the summer phase for radiant air conditioning.

Controlled mechanical ventilation system (VMC)

This system integrates a system that constantly reciprocates the air mechanically inside the house by recovering the heat in the outgoing air (enthalpy) and a the system that will dehumidify the air in the summer phase to make the room perfectly air-conditioned.

The VMC is from Zhender Company, a leader in this field.

La mechanical ventilation reciprocates air constantly, taking it from the ‘dirty’ compartments (bathroom, kitchen, laundry room) and putting it back into equiportment in the noble compartments (bedrooms, living room…). This replacement is done through a machine that recovers the heat from the extracted one by preheating the newly introduced replacement one.

The dehumidifier is installed on the ventilation supply so that it can be provided dehumidified in the summer phase. This allows, in conjunction with radiant cooling panels in the summer period, to provide radiative air conditioning in the warmer periods.