Energy efficiency and zero consumption goal

High Energy Efficient Homes: The Zero Energy Building (ZEB) Zero-consumption houses are no longer an unattainable dream, but an established building practice, as enshrined in the European Community’s 20-20-20 directive. This ambitious goal promotes energy efficiency and sustainability for all member states. To learn more, you can visit the official website: 20-20-20 Directive. An Evolution […]

A disaster that must give us pause

The disaster that has struck the forests of northeastern Italy in recent days has filled all nature and wood lovers’ hearts with dismay however, it is a disaster that should give us pause. It is a disaster that gives pause for thought to all operators and users of the wood product in our region and […]

Earthquake prevention day

October 20, 2019 has been declared to be Earthquake Prevention Day. It will be a Sunday when technical professionals will take to the streets to talk about prevention. https://www.giornataprevenzionesismica.it/ For our part as wood designers possimao say that we are very interested in seismic prevention and that building with wood is the best seismic prevention […]

The delamination test, an important information on the strength and durability of wood structure

In each supply of X Lam panels, the delamination test is performed to check the strength of the glue joining the cross planks forming the panels. The durability of the wood is virtually unlimited with the delamination test the strength of the glue that joins the components is checked in order to assisure that the […]

In France, 50% of the structure of public buildings will have to be made of wood

President Macron has announced ato a very advanced sustainability law that will ensure that all new public buildings are constructed with at least 50 percent wood or other natural materials. An interesting lesson for all The measure will be implemented by 2022 and will affect all public buildings financed by the French state, according […]

X Lam and construction wood can actively contribute to the fight against global warming

The Carbon Cycle and Sustainable Management of Woodland Heritage. In recent years, the increasing concentration of carbon in the atmosphere has generated devastating effects, such as global warming, pole melting and a series of extreme weather events. These phenomena are mostly the result of CO2 emissions from human activities, mainly from the burning of fossil […]

The foundation of a wooden house

Slab Foundations for Wooden Houses: Foundations for a Sustainable Future. The foundation of a wooden house is a crucial element that deserves careful and detailed planning from the earliest stages of the project. Although foundations may seem an unglamorous topic, their importance cannot be underestimated, as they not only support the entire structure but also […]

XLam: the new reinforced concrete

XLam is often considered the new green version of reinforced concrete perfect for civil, residential and other buildings. It is a wood panel made from extremely versatile cross-fiber rough planking that replaces traditional brick masonry. Similar to traditional masonry, XLam simultaneously provides protection from the outside and load-bearing capacity. XLam like all masonry has a […]

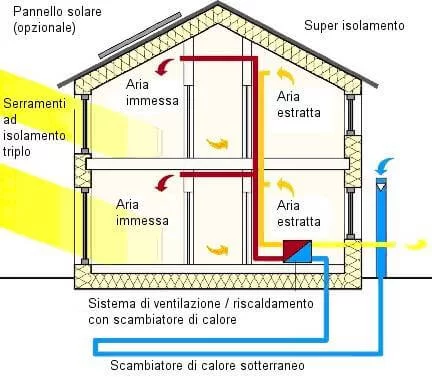

A modern wooden house: design and energy saving

A wooden house does not have to have a rustic look! A log house in the collective imagination is the log house of the Nordic tradition. Even today for rustic lovers we can make the log-house and sometimes we are even asked for it, however in reality today the log house is a very different […]